120mm stunt scooter wheels rawing aluminum core material cutting

The first step in the production of scooter wheels is the cutting of aluminum raw materials.Workers will cut the uniform size of the wheel according to the product specifications,after the unified measurement confirms that the specifications are correct, then it will be sent to the next production process for processing.

Share:

-

120mm stunt scooter wheels rawing aluminum core material cutting

120mm stunt scooter wheels rawing aluminum core material cutting -

FOX PRO two-row solid color wheel 62×44MM

FOX PRO two-row solid color wheel 62×44MM -

7005 aluminum alloy Competition Series Speed Skating Frame

7005 aluminum alloy Competition Series Speed Skating Frame -

FOX PRO High Performance Mirror Hollow Wheel

FOX PRO High Performance Mirror Hollow Wheel -

FOX PRO Aluminum Wheel Core High Resilience Roller Skate Wheels

FOX PRO Aluminum Wheel Core High Resilience Roller Skate Wheels -

FOX PRO Flash Crystal Transparent Roller Skate Wheels

FOX PRO Flash Crystal Transparent Roller Skate Wheels -

High-performance double row roller skates

High-performance double row roller skates -

Promisesport factory for stunt scooter and inline speed skates

Promisesport factory for stunt scooter and inline speed skates -

Wonderfox / Promisesport factory with FOX PRO skates

Wonderfox / Promisesport factory with FOX PRO skates -

7005 aluminum stunt scooter assemble

7005 aluminum stunt scooter assemble -

stunt scooter and speed skate frame aluminum material CNC department

stunt scooter and speed skate frame aluminum material CNC department -

carbon fiber layer sewing department

carbon fiber layer sewing department -

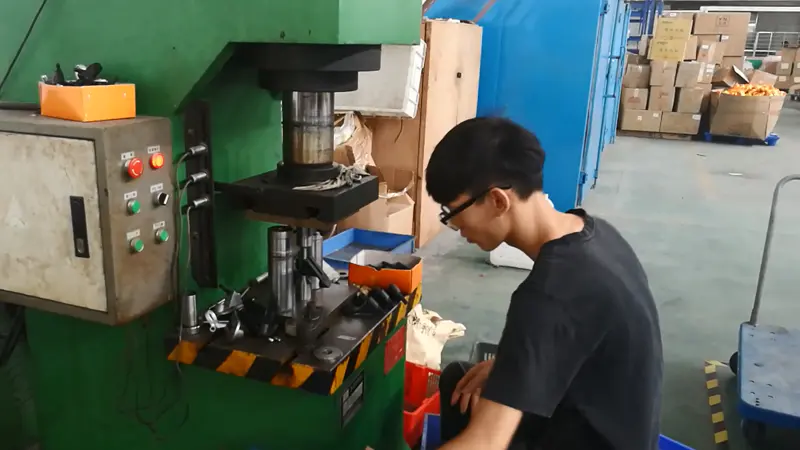

stunt scooter wheels production department

stunt scooter wheels production department -

62x42mm quad skate wheels screen printing department

62x42mm quad skate wheels screen printing department -

110mm pro scooter wheels vacuum packing

110mm pro scooter wheels vacuum packing -

100mm stunt scooter wheels vacuum packing

100mm stunt scooter wheels vacuum packing -

inline skate shoe Upper emboss

inline skate shoe Upper emboss -

microfiber leather upper sewing department

microfiber leather upper sewing department -

4x110mm inline speed skate quality inspection

4x110mm inline speed skate quality inspection -

stunt scooter rawing 7005 aluminum material cutting

stunt scooter rawing 7005 aluminum material cutting -

BMX stunt scooter computerized numerical control

BMX stunt scooter computerized numerical control -

quad skate aluminum plates die casting machine

quad skate aluminum plates die casting machine -

stunt scooter deck CNC milling machine

stunt scooter deck CNC milling machine -

pro scooter deck rawing aluminum material cutting

pro scooter deck rawing aluminum material cutting -

4 wheels quad skate aluminum trucks component assembly

4 wheels quad skate aluminum trucks component assembly -

ABEC-11 608 bearings assembly

ABEC-11 608 bearings assembly -

kick scooter inventory area

kick scooter inventory area